130

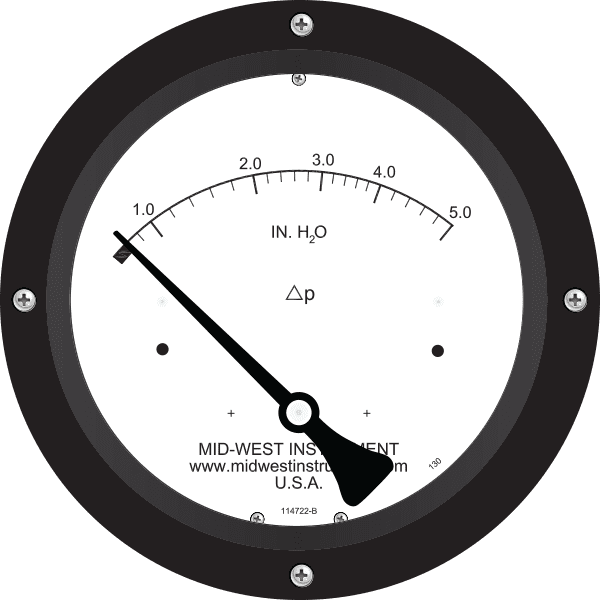

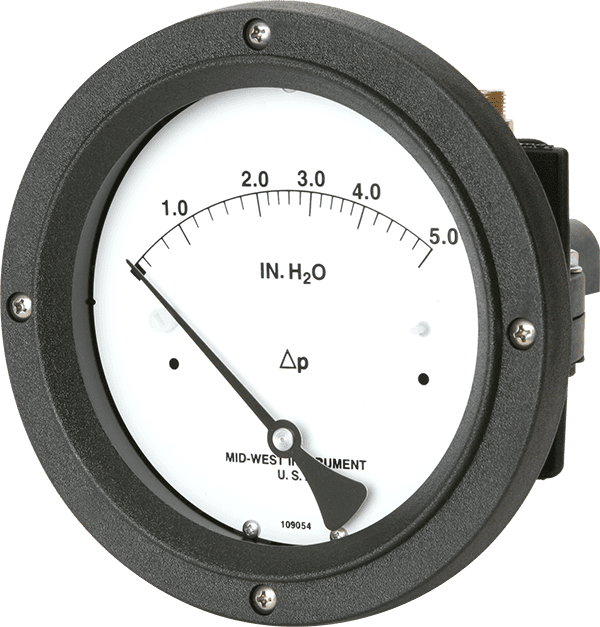

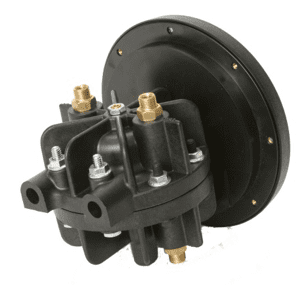

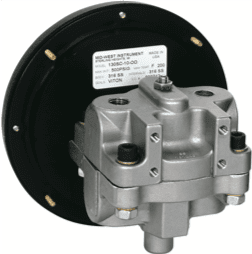

Diaphragm Type Gauges

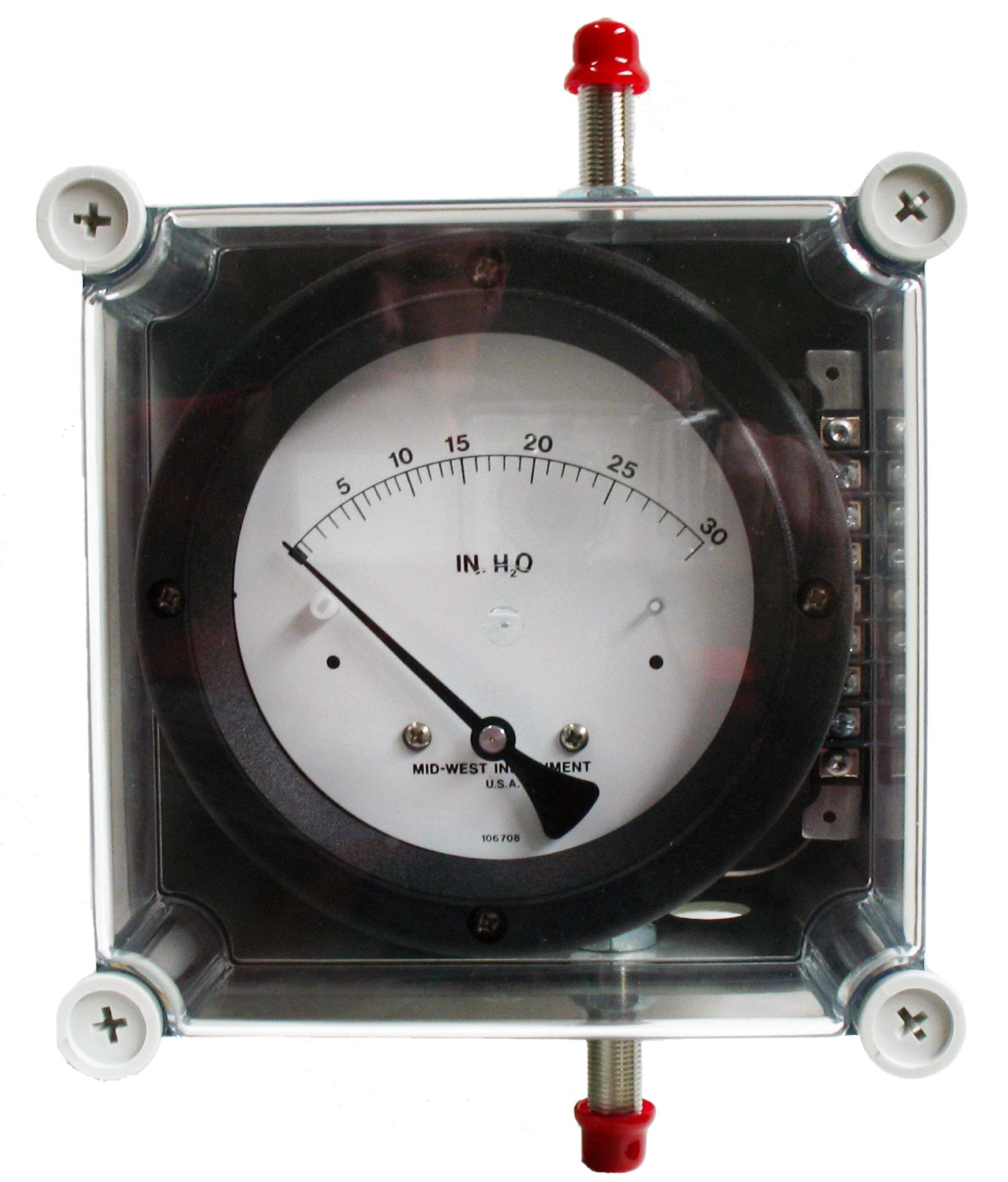

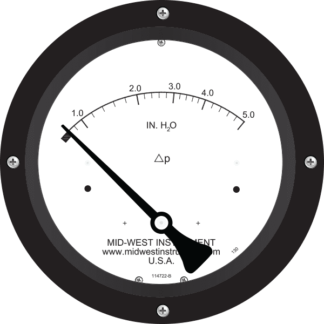

130-PC-00-OO

300 P.S.I.G. Working pressure, glass-reinforced engineered plastic body, 316 stainless steel internal metal parts, (Two) 1/4″ carbon steel compression tube fittings ***

130-AC-00-OO

500 P.S.I.G. Working pressure, aluminum body, 316 stainless steel internal metal parts, dual 1/4″ FNPT connections, top & bottom.

130-BC-00-OO

500 P.S.I.G. Working pressure, brass body, 316 stainless steel internal metal parts, dual 1/4″ FNPT connections, top & bottom.

130-SC-00-OO

500 P.S.I.G. Working pressure, 316 stainless steel body, 316 stainless steel internal metal parts, dual 1/4″ FNPT connections, top & bottom.

Product Features and Benefits

- Total separation of high and low by a convoluted elastomer diaphragm.

- Sensor magnetically coupled to the indicating pointer and optional switches.

- Suitable for use on virtually all reasonably clean liquids or gases.

- Over-range protection to full rated working pressure.

- Diaphragm design allows use of dissimilar fluids on high and low side of gauge.

- Can be used with vacuum or pressure applications

- Weatherproof rated to NEMA 4X/IP65.

- Body Materials: Glass Reinforced Engineered. Plastic, Aluminum, 316L Stainless Steel & Brass

- Working Pressure: 300 PSIG Glass Reinforced Plastic Body

- Working Pressure: 500 PSIG Aluminum, Brass and 316 S.S. Bodies

- Shatter resistant lens.

- 4-1/2″ Round Engineered Plastic Dial Housing Assy. (Standard)

- Operating Temp. -40° F to +200° F (-40°C to +93°C)

- DP Ranges available in: Inches H2O, PSID, mbar, and Kpa

- Also available with Square Root dials for flow measurement (Please contact Mid-West at 1-800-648-5778.)

The low range capability of the Model 130 is ideally suited for flow, liquid level and vacuum applications. Magnetic coupling between the sensing element and the indicating pointer provides for complete isolation of the process fluid within the pressure capsule. The few internal metal parts are 316L Stainless Steel.

Common Applications: Tank Level Monitoring Horizontal or Vertical Flow, Liquid Level, Indication/Balancing, Filter Monitoring for Gases, Water Treatment Applications and Vacuum Application.

From: $0.00

The Mid-West Advantage

- 5 year warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM and Private Label Capabilities

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System CSA B51-09 SAI GLOBAL

- UL Listing

- CSA Listing

130Specification